EMC Wafer Laser Micromachining System

| EMC Wafer Laser Micromachining System |

| FCM 8401 features a mulifunctional EMC wafer laser micromachining system designed for 3D IC and FOLOP applications. It supports 300mm EMC wafer trimming/grooving, notch cutting, and ID marking. With precise wafer alignment and control, it completely removes EMC residue without damaging the carier glass, improving debonding yield and reducing the risk of wafer cracks. |

- Markets

Wafer-Level Packaging Process,3D IC 、FOLOP

- Applications

EMC Trimming / Grooving, Notch Cutting, ID Marking

- Materials

Epoxy Molding Compound(EMC)

■ Multifunctional laser micromaching system

■ Applied on Ø300 mm EMC wafers 3D IC/FOLOP packaging

■ Non-contact cleaning, precise EMC wafers removal, no residue, no glass damage

■ In-house optical design for better thermal control and better quality

■ Throughput:≧ 15 WPH

■ Particle & ESD control

Processing Technology

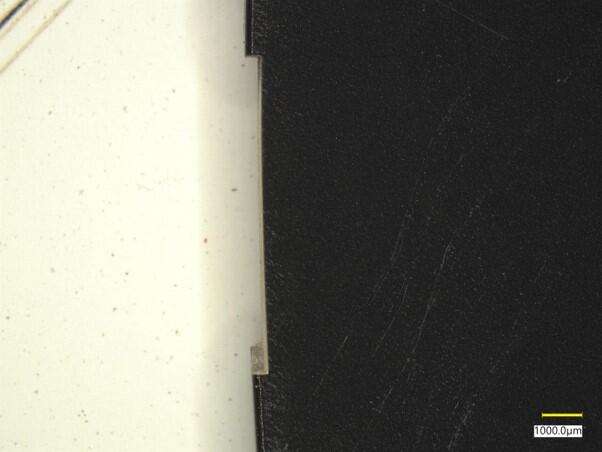

Trimming / Grooving

Pico IR laser precisely removes EMC with no residue or carrier glass damage, ensuring de-bonding yield and reducing wafer crack risks.

Notch Cutting

recisely aligning to the notch for cutting, exposing the carrier glass edge without damage, and improving post-process alignment accuracy.

ID Marking

EMC wafer serial marking with SEMI standard fonts for production traceability.

Why FitTech?

FitTech focus on design and manufacturing photoelectric related system. We provide accurate and exquisite processing quality with leading R&D capability.

With well experienced and our completed and elite R&D team, customized such as automated, integrated with robot, system integration, etc. are all available.

FitTech's Laser cutting/drilling Machine that design and manufactured in Taiwan. And we also provide instance after service by our elite technical team.