Laser Diode The application of Laser diode

With the continuous expansion and growth of LiDAR's application, such as optical communications, 5G, 3D sensing, and automotive applications, Significant increase in demand of surface-emitting lasers (VCSEL, PD) and edge-emitting lasers (DFB, FP, EML), which drives the demand for test equipment. FitTech has invested in the development of laser diode component test equipment for many years. It provides customers with a full range of test solutions, and support customized and integrated test equipment according to customers' relevant test requirements.

General measurement of Laser Diode - LIV measurement

LIV measurement is mainly for current, voltage and optical power measurement of LD components. The complete measurement data can be obtained through data calculation and image processing. The test equipment from FitTech support integrated voltage/current pulse measurement (Pulsed optical measurement) functions which minimizes self-heating of the DUT and effectively obtain test values to investigate the DUT performance.

General measurement of Laser Diode – Optical Spectrum analysis

Optical spectrum analysis is one of the test parameter of various types of LD (VCSEL/DFB/FP/EML). The LD related tests provided by FitTech can support TO-CAN monitoring measurement, high/low temperature control system, OSA integration and other functions. We also provide customized integration according to various customer’s requirement.

High/Low temperature control system

Integrate temperature control system to perform measurement at -40℃~95℃.

Low temp. test

Room temp. test

High temp. test

Why FitTech

| others | FitTech | |

|---|---|---|

| Testing condition | Fixed and irreversible item | Customized integration |

| Automation and merchandise | Fixed solution | Customized integration of Prober and Tester |

| Software interface | Independent development | Independent development |

| sales and technical teams | Incomplete equipment information | Vertical integration and face to face service with years of experience |

| After service | Mostly located oversea with long response | Having service center both in domestic and overseas |

Please contact us for detailed equipment specification information or functional integration requirements.

Testing condition of VCSEL

With the fermentation of terminal applications, the demand for VCSEL component capabilities has increased, with more sensitivity, longer sensing distance, and higher PCE (photoelectric conversion efficiency). Therefore, relevant data monitoring during testing has become an important basis to improve component performances.

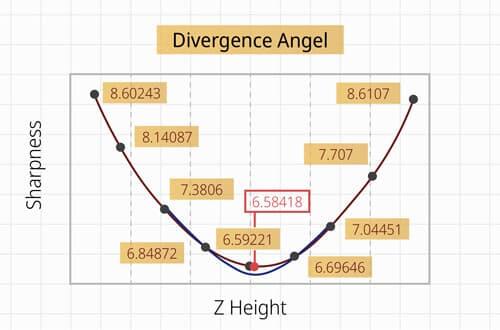

The VCSEL Prober and Tester from FitTech supports highly mechanism integration and testing stability. To support 4-6 inch wafer level and high power VCSEL testing. The corresponding model type can provide various testing items, such as Near Field Pattern, Far Field Pattern, eye safety, divergence angel, M2, Emitters distribution, uniformity and so on.

Uniformity & Leveling of emitters

Emitters amount and Beam waist diameter

Emitters distribution

M2 measurement

Divergence Angle

Eye Safety

Testing Solution of VCSEL

FitTech possess excellent optoelectronic integration technology with years of experience. We also have an ability to equip with self-developed control software, humanize to setup testing parameter and obtain testing report. It can judge good and bad die on VCSEL testing equipment and also record every testing data, to analysis DUT performance. The testing data can support chip manufacturer to investigate relative parameter and elevate product efficiency.

Please contact us for detailed equipment specification information or functional integration requirements.

Testing Condition of PD

PD (Photodetector) plays an important role as a photodetector in the field of optical communications and automotive LiDAR which with fast response of sensitivity. FitTech provides high mechanism integration and high testing stability equipment, which can collocate with corresponding standard light sources and perform PD component responsivity, CV / IV measurement to assist customers in judging important features of PD performance.

Responsivity

Auto Coupling

CV-IV measurement

Testing Solution of PD

FitTech possess excellent optoelectronic integration technology with years of experience. We also have an ability to equip with self-developed control software, humanize to setup testing parameter and obtain testing report. It can judge good and bad die on PD testing equipment and also record every testing data, to analysis DUT performance. The testing data can support chip manufacturer to investigate relative parameter and elevate product efficiency.

Please contact us for detailed equipment specification information or functional integration requirements.

Testing items of DFB/FP

FitTech's equipment has a high level of mechanical integration, providing automated DFB/FP/EML point testing and sorting equipment. For chip and bar measurement items, it includes wavelength measurement and FFP measurement. Moreover, depending on customer requirements, it can integrate DFB chip appearance inspection (AOI/VI), OCR function for chip ID, loading and unloading jig customized, and other functions.

Smart Optical Character Recognition and automatic probing and testing system increase processing efficiency, monitoring the DUT performance and elevate issue Retrospectivity.

Appearance inspection (AOI/VI)

Optical character recognition

Input and output stage for Wafer/ Gel Pak

Testing items of EML

EML testing equipment can support automatic probing and sorting, include DFB measurement, EA measurement and SOA measurement. It can according to customer’s requirement to integrate high/low temperature inspection, AOI/ VI, OCR and customized input/output form for DUT.

DFB measurement

EA measurement

SOA measurement

Testing solution of DFB/FP/EML

FitTech possess excellent optoelectronic integration technology with years of experience. We also have an ability to equip with self-developed control software, humanize to setup testing parameter and obtain testing report. It can judge good and bad die on DFB/FP/EML testing equipment and also record every testing data, to analysis DUT performance. The testing data can support chip manufacturer to investigate relative parameter and elevate product efficiency.

Wafer scribing/breaking

Wafer scribing and breaking are crucial processes in the semiconductor and optoelectronics industries. After defining the dimensions through wafer scribing, the wafer is broken into bars or chips. The stability, yield rate, and efficiency of the breaking process are critical factors affecting overall production capacity.

Wafer scribing

FitTech's wafer scribing equipment provides surface scribing before wafer breaking. It supports 6"-8" compound semiconductor materials , such as GaAs, GaN, InP, etc. wafers and is equipped with an automatic positioning system.

Wafer breaking

FitTech's wafer breaker utilizes ceramic blades to break wafers. With adjustable breaking angles and elastic structure design supports to adjus breaking force for different thickness of wafers. The software supports image recognition, automatically aligning the blades' processing angles and enhancing production yield.

Wafer material

GaAs wafer

GaN wafer

InP wafer

Please refer to other pages for VCSEL/EEL/PD testing items. For detailed equipment information or specific requirements, feel free to contact us.

Know more about optoelectronic semiconductor test solutions

Burn-In testing

Burn-In testing is a procedure used to screen potential failure risks in chips. It simulates actual usage conditions to test the chips under different temperatures, voltages, or currents, to ensure the stability and reliability of the product. FitTech 's Burn-In testing equipment is suitable for LD/PD products with different packaging forms such as TO-CAN, COS, COB, etc., and can provide corresponding burn-in trays. To meet different testing requirements, we offer a constant temperature environment and stable power supply system, with the capability to monitor the test items regularly to confirm if there are any abnormalities.

TO-CAN testing

COS testing

COB testing

Test Mode

We offer different power supply systems, including ACC or APC aging modes, CW mode, or Pulse mode power supply formats. Additionally, testing temperature and current can be independently set in the software.

Temperature/current setting

CW power supply mode

Pulse power supply mode

For detailed equipment specifications or further requirements, please feel free to contact us.

Know more about optoelectronic semiconductor test solutions